The on-site commercial food waste digester is a rising star of sustainability. Environmentally aware companies use tens of thousands of digesters globally to process food waste efficiently, reducing waste sent to landfills and avoiding squandering their companies thousands of dollars.

The HomeBiogas system has for the past 5 years been used for home food waste to generate gas for heating stoves, now a new product will soon be available from the same manufacturer to heat water in a commercial kitchen environment.

An Easy On-site Food Waste Solution

Other products are also available which eliminates the need for costly food waste collections. But before you buy make sure the unit complies with all EU safety standards (RoHS Compliant). The manufacturers offer a range of sizes to suit all commercial volumes.

The most sophisticated on-site digesters even provide a personalized dashboard that will allow you to analyze real-time data, create customized reports, and look at the amount of food waste diverted over time

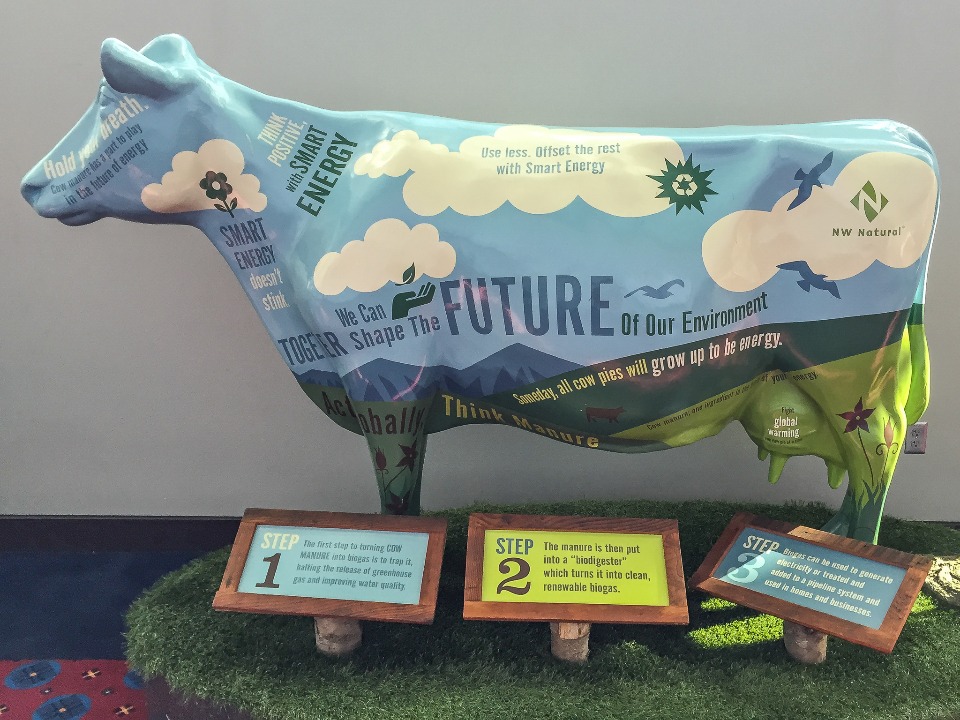

How the On-Site Commercial Food Waste is Digested at the Kibbutz Yagur

An on-site commercial HomeBiogas system in the Kibbutz Yagur, located in northern Israel near Haifa, turns 440 lbs (200 kg) of food waste per day (including meat, fish, and dairy) into renewable gas that is used to heat water for the dishwasher in the kitchen.

The food waste is generated by the common kitchen and communal dining room, which are both utilised by residents of the kibbutz to prepare meals for themselves. It is fed into a grinder, which mechanically feeds it into the digester tank, which holds 3,700 gallons.

The amount of biogas created might also be used to generate up to 200 kWh/day of power, resulting in a reduction in greenhouse gas emissions of 1 ton/day. Previously, around 4 tonnes of food waste every month were taken to the dump.

The digester’s physical footprint is approximately the same as that of two parking spots.

There is a 50-day retention time in the digester, which operates at 95 degrees Fahrenheit (35 degrees Celsius), and pathogens are eliminated as part of the process.

The digester is heated by re-circulating heat from the mixing pump that serves it.

The biofertilizer is discharged into a tank at a rate of fifty gallons per day. In addition to trees on the kibbutz’s pathways and a self-sustaining garden surrounding the commercial system, the fertiliser is applied to other plants in the garden.

There is a connection to the sewer system in case of an emergency or to dispose of any unused fertiliser if necessary.

It is anticipated that HomeBiogas would deploy its commercial solution for industrial kitchens in the United States by late 2022, following the completion of the beta phase.

The post on-the website of Biocycle where this section appeared first provides further info on this subjec.

Testimonials

We were able to reduce the amount of trash that was being collected and went to the landfill and the cost of waste that was disposed of for each event and non-event date. Environmental issues are the top priority for us. But the majority of our actions to promote the environment have impacted our profits for many years. Doing it this way the reverse has been true.

Our view is that there will be a 24-month repayment on our on-site digester, due to reduced garbage disposals. The way I look at the garbage I’m getting from the kitchens has changed. It is now having a positive effect on our costs every hour, day, week or month. But, it’s important to me that we use remote monitoring to monitor waste. That way we are able to find and solve expensive and wasteful waste disposal practices at each site.

I will be driving our organization to zero waste so a weighing capability and remote reporting are important to me.

Technologies: Food Waste Liquefiers

Commercial vendors sell liquefied food waste products or biodigesters to companies and institutions in California that produce large amounts of food waste like restaurants, grocery stores, hotels, supermarkets, universities, and prisons.

This website offers information to help evaluate whether or not these technologies are appropriate for their facilities. CalRecycle strongly recommends generators contact these organizations for support in completing their project requirements.

Proper handling of food waste

Industries that are served:

- Food Markets and Grocery Stores

- Convention Centres

- Clinics for Education and Healthcare

- Hospitals

- Offices

- Lodgings

- Casinos

- Hotels

- Restaurants and Resorts

- Fine Dining Casual Dining

- Supermarkets

- Food Co-ops

- Airports

- Amusement Parks

- Recreation Venues

- Entertainment Mall

- Cruise Ships.

Food waste is considered solid waste in states regulations and is needed to be taken out of businesses and residences once per week to an approved disposal centre. Besides state regulations, the handling of hazardous material is sometimes subject to city regulations.

Food waste is considered solid waste in states regulations and is needed to be taken out of businesses and residences once per week to an approved disposal centre. Besides state regulations, the handling of hazardous material is sometimes subject to city regulations.

The removal of liquefied food waste in discarded packaging is a process for sustainably disposing of them. Only the operators who satisfy all the required local or state laws may dispose of solid waste, including liquefied foods, in an efficient manner. Liquefied food residues may also be used as feedstocks of the anaerobic digesters.

Find an anaerobe digestion facility in the vicinity of you and send you grocery store’s waste there. Check with your local recycling coordinator to find a compost facility near you that is permitted to accept food waste.

ORCA is an innovative food waste solution

Digester technology mimics a naturally occurring digestion process. The method follows the same principles as all living organisms. ROCA enables micro-organisms to digest food in an efficient and thermophilic manner.

OCAR provides a hyperlocal, distributed alternative system of collecting trucks and bins. Our system provides considerable savings because it eliminates truck parts transport in the process, while minimizing harmful emissions associated with truck traffic.

Reducing food waste with sustainable solutions – Divert Food Waste from Landfill

In 2018, 35% of the 229 million metric ounces of American produce was unaddressed. The vast majority of these food items were sent directly into landfills. Food waste is an enormous environmental impact since the food that is not eaten has the ability to be grown, harvested, transported, cool water and cooking gas provided, even when it is discarded by humans.

Food waste is recognized by some to be an emergency problem in all corners and must be immediately dealt with.

The journey continues

Once at a wastewater treatment station (wastewater treatment facility), the ride doesn’t end. It is then possible to use liquids as a source of renewable and sustainable electricity. Integrated food waste reduction systems reduce food waste by reducing the use of landfill waste.

The diversion of landfills reduces greenhouse gases as well as CO2. ORCA also aids in improving worker productivity by keeping workers in kitchens and decreasing strains and sprains.

Climate change

The reduction in the use of food waste from landfills is beneficial in the context of climate change. Landfill reduction in pollution could outweigh other reductions or emissions associated with the organic management strategy. The use of food waste in the treatment of wastewater may lead to further greenhouse gases reduction.

Which model is right for you?

With four models, ORCA can accommodate the size of food waste in cooking. ORCA models have onboard scales to monitor your food waste and weigh it. The scales are connected to the proprietary ORCA Portal a personalized dashboard that lets you analyse real-time information and generate customized reports of your recycling.

There are four food waste management pathways. Of those, transporting anaerobically digested waste through the sewer to a wastewater treatment plant for further treatment is a popular option.

Ready to make a difference?

The business model is divided into renting/buying or renting depending on what type of business you require. Our technologies are fully integrated to our services so they will suit the needs of our customers, to ensure that our systems work seamlessly with our customers. Just feed your ORCA.

This technology creates meaningful cost savings for customers while diverting food waste from landfills. Landfill diversion reduces both carbon dioxide and methane gas emissions.

Food waste processing at the source successfully diverts waste from tips, saving you thousands of dollars while also lowering carbon emissions and toxic methane that contribute to climate change.

Introducing Baby Orca

ORCA is pleased to offer a solution for reducing the environmental impact on the restaurant business. Why do we need ORCAs in order to join ORCA families and how can it make a difference?

By using microorganisms the system is able to digest food waste while starting the breakdown of fats, oils and grease (FOGs).

The Baby Orca is said to deliver a solution that will assist our clients in mitigating the carbon footprint of their dining operation. It is a sustainable and affordable food waste solution. Less food waste to transport takes trucks off the road and improves an operation’s overall carbon footprint.

Which model is right for you?

It is essential to create the perfect thermophilic biological environment for the microorganisms to digest food waste into a liquid.

With four models, ORCA can accommodate the size of all food waste in cooking. Models have onboard scales to monitor your food waste and weigh it. The scales are connected to the proprietary ORCA Portal a personalized dashboard that lets you analyse real-time information and generate customized reports.

Models are available for all food waste volumes and all space limitations.

Bear in mind that there may be additional sewer fees assessed if food waste reduction strategies include liquefiers and the use of public sewage lines or public wastewater treatment plants, and facilities using liquefiers will need confirmation that the system will recycle the liquefied food as the end use for this material will be a deterrent to using the liquefiers.

Other considerations

Residual liquids from wet systems

In the case of food waste liquefied systems, residual water is never used for irrigation. Food waste liquefiers must be linked to the sewer system in order to have effluent treated at the disposal site.

But when done well these systems improve the waste management process to divert waste from landfills, reduce costs, improve operations, and minimize negative environmental impacts for organizations across the world.